Innovating beyond boundaries: the Defta journey

Whether it’s product or manufacturing process, technical, environmental, or economic advancements, the Defta teams’ appetite for innovation and continuous improvement is insatiable.

Innovation at Defta

Staying at the cutting edge of technology to serve you better

At Defta, we believe in the power of Data, throughout the value chain. We guarantee our customers’ satisfaction by meeting their deadline, quality and cost requirements, even in the face of the most complex challenges. Our ability to adapt to both market demands and digital developments means we can stay at the cutting edge of technology and offer our industrial customers ever more innovative products and services.

“We have strong expertise in A.I. at Defta, always striving for greater performance and quality in the delivery of our customers. Our Process and Technology unit has developed and implemented several instances of neural networks in-house to improve quality control and online performance.”

We are constantly looking for more tools to meet our customers’ demands and increase our flexibility. Modern technologies are helping us to optimize our supply chain and we are striving for an ever more connected factory. As part of our drive to remain competitive in a fast-changing market, we work with partners who share our aspirations in terms of innovation. In this way, we continue to improve all the time, with the aim of meeting the needs of our industrial customers as effectively as possible.

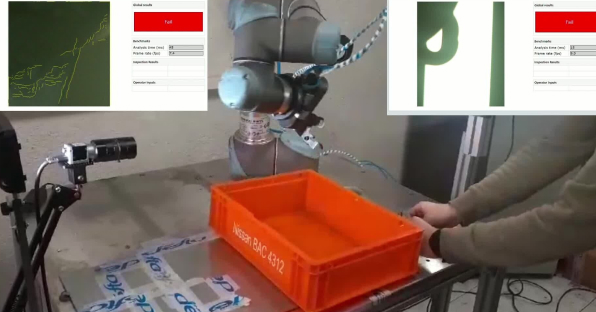

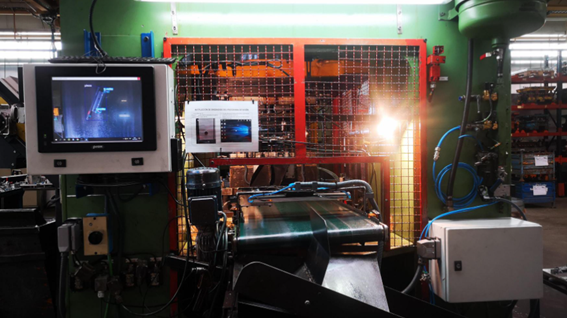

- Visual detectionVisual detection refers to the use of cameras and computer vision algorithms to analyze images or video feeds in real-time. Defta utilizes visual detection technology to identify defects, monitor processes, or enhance security by recognizing objects or patterns.

- Vibration Real-time QCVibration real-time quality control (QC) involves the continuous monitoring of machinery vibrations to assess their performance and detect any anomalies or potential faults. Defta employs this technology to ensure the reliability and efficiency of equipment and to preemptively address any issues before they escalate.

- Process OptimizationProcess optimization entails the systematic improvement of production processes to enhance efficiency, quality, and resource utilization. Defta leverages various techniques such as data analysis, modeling, and automation to optimize workflows and achieve higher productivity while reducing costs.

Innovating beyond boundaries • Innovating beyond boundaries •

- Artificial IntellligenceArtificial intelligence (AI) refers to the simulation of human intelligence processes by machines, particularly computer systems. Defta integrates AI algorithms and machine learning techniques into its operations to automate tasks, gain insights from data, and make informed decisions, leading to improved performance and innovation.

- Neural Networks (CNN for Quality)Neural networks, particularly Convolutional Neural Networks (CNNs), are utilized by Defta for quality control purposes. CNNs are specialized neural networks designed for image recognition tasks, making them ideal for analyzing visual data and identifying defects or anomalies in manufacturing processes.

- AGVs (Automated Guided Vehicles)AGVs are autonomous vehicles equipped with navigation and control systems that enable them to move materials or products within a facility without human intervention. Defta deploys AGVs to automate material handling tasks, streamline logistics, and optimize workflows in warehouses or manufacturing environments.

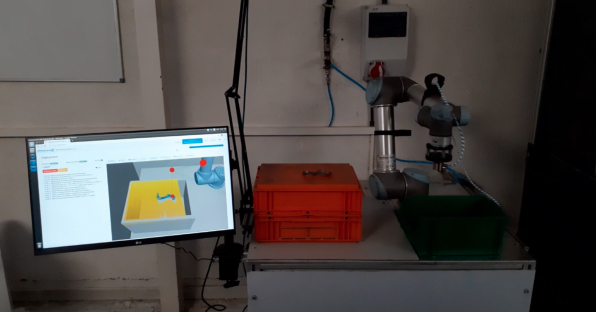

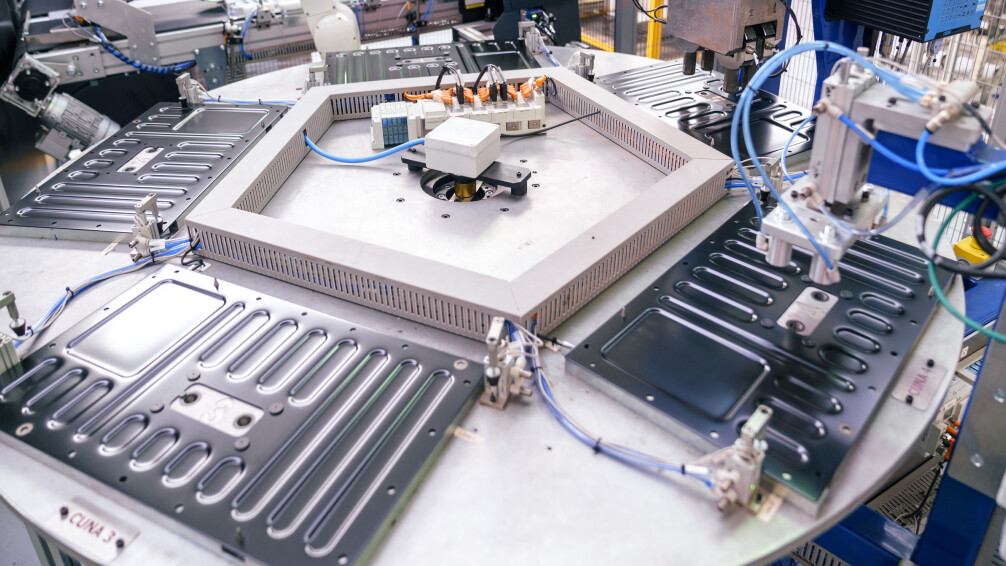

Pick & place

Pick and place refers to the process of picking up an object from one location and precisely placing it in another. Defta has developed an updated version (V2) of its pick and place system, incorporating enhancements and optimizations based on its internal standards to improve efficiency and accuracy.

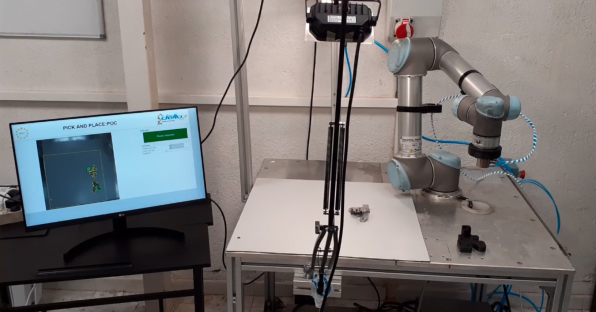

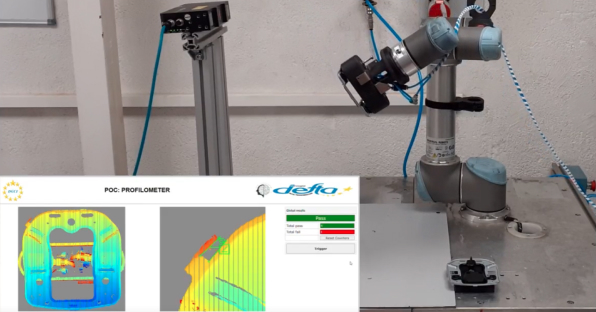

UR robotic arm

This video demonstrates the integration of a camera system with a Universal Robots (UR) robotic arm. Defta has established an internal standard for this integration, allowing for seamless communication and coordination between the camera and the robotic arm for tasks such as object recognition and manipulation.

Defta’s internal standard ensures the optimization and reliability of this integration, facilitating smooth operation and improved productivity.

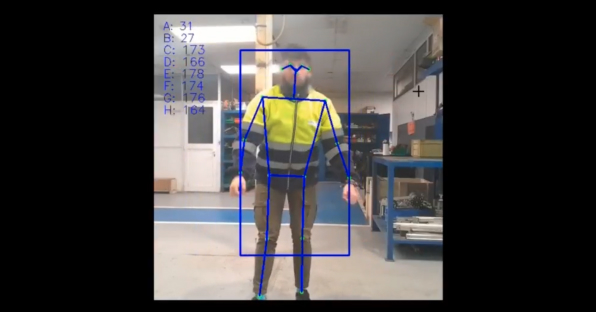

Pose control

Pose control involves precisely controlling the position and orientation (pose) of an object or tool. Defta’s Pose Control 2 system, built according to its internal standards, provides advanced capabilities for accurately manipulating objects or tools in various applications, enhancing overall performance and flexibility.

Ready to learn more?

Our team is here to assist you with any inquiries or information you may need.

Know-how

Our value-added is a determined commitment to innovation, which allows us to implement the latest market technologies in fine blanking, stamping, welding, plastic injection, heat treatments and assemblies.

Processes

As an automotive tier-1 manufacturer, Defta has expertise in designing, integrating and manufacturing even the most complexes assembly processes, while striving for performance and quality.